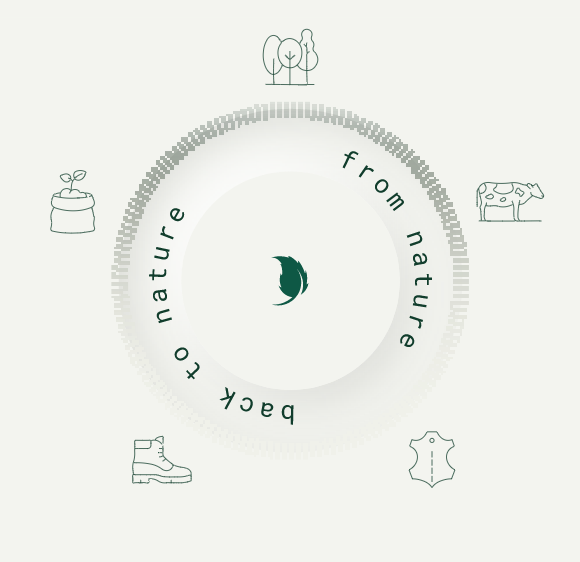

In a circular economy, what was previously considered waste is now a resource that can be reused and reintroduced into the production cycle. Biocircular Ecotan thinking takes this a step further by employing materials that start and end with nature, without causing problems in the future.

Completing the loop is the new standard to preserve the planet earth. Ecotan, the world’s first biocircular 100% metal free leather tanning formulation, is designed to meet the latest environmental regulations and be a key tool for brands looking to rise to the challenge.

This new frontier in sustainable leather solutions, representing Made in Italy excellence, comes as a result of a half decade of continuous innovation conducted at Silvateam Research & Development centers and in close partnerships with prestigious universities, research institutes, tanneries and recycling companies.

Silvateam has created a tanning system that matches the performance of chrome and glutaraldehyde tanned leather without using harmful substances. We took a traditional natural material and transformed it through science into something new. The result of Silvateam’s engineers efforts is a new class of biocircular synthetic tannins based on and designed to work with chestnut, gallnuts and other extracts.

They mimic the structure of natural tannins with a smaller, simpler molecule that gifts the leather with the qualities required by the footwear, leather goods, automotive, upholstery and design industries. Our eco-conscious products are certified ZDHC level 3 and PFAS free.

While natural tannins are the primary tanning agents in Ecotan solutions, to deliver leathers that meet commercial standards and a wide range of style, additives, colors and finishes are required in the later stages of tanning. Silvateam, in partnership with Biofin Leather (Gruppo Biokimica), has carefully selected a variety of finishing products that pose no toxic threat in the production of Ecotan leathers and, subsequent, consumer use.

Leather items designed to be fully circular are the necessary next step if we are to preserve our planet and ensure a bright future for our children and generations to come. Next-gen circular materials engineered to be repurposed at end of life are becoming more available to designers. Thanks to this approach, finished products can eventually rejoin nature’s cycle.

Other repurposing paths available are: biodegradability, biodegradability in compost, biochar, etc.

Ecotan's biocircular No-Waste Journey