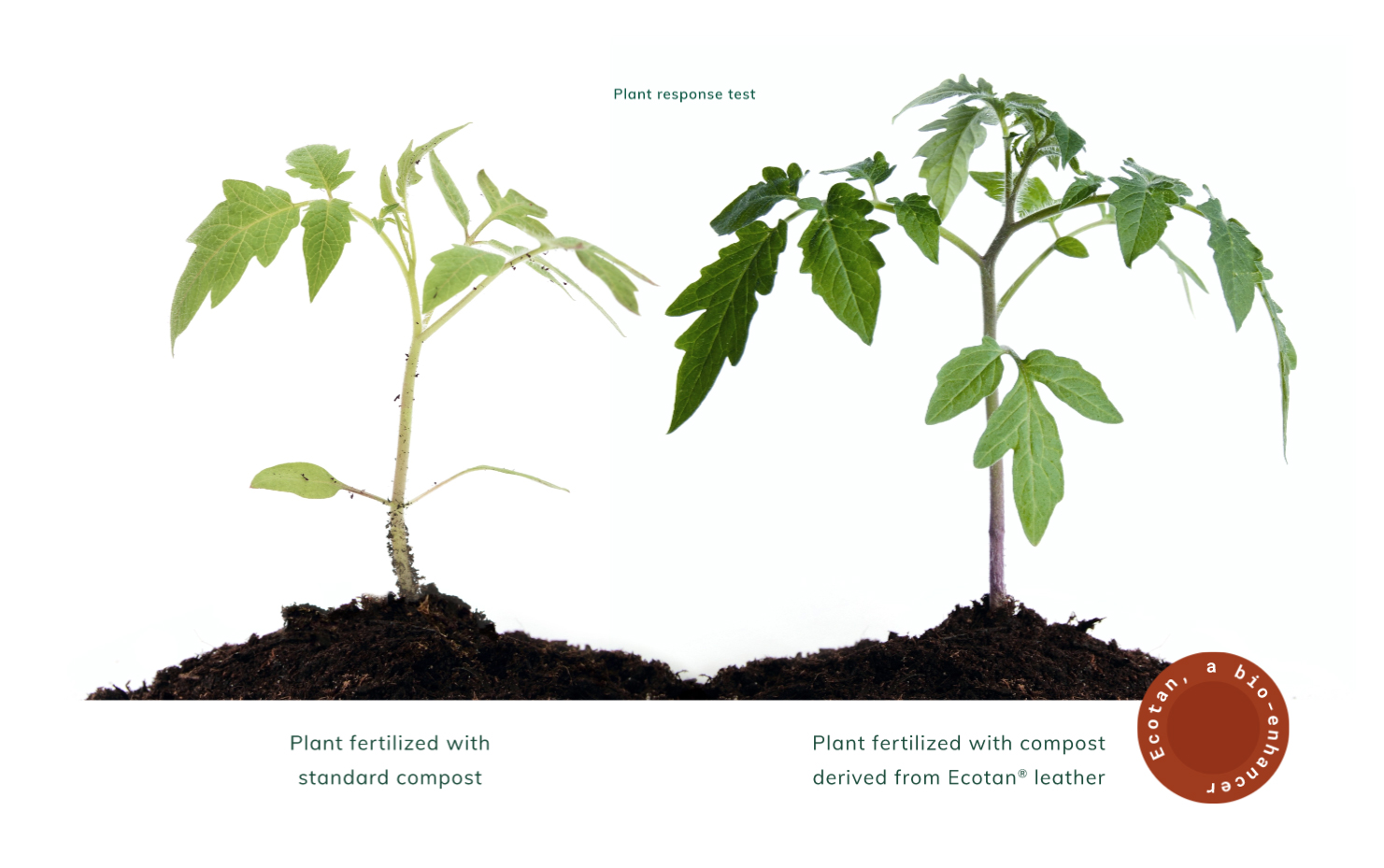

Ecotan leather scraps and articles are given a new life as a fertilizer that releases back to nature the nutrients originally taken ‘on loan’ from the hide.

A chemical process, called hydrolysis, is used to break down leather proteins into simpler molecules made up of carbon and nitrogen. The result, a protein hydrolysate, is used to make a granular fertilizer that contains organic substances, nitrogen and phosphorus, engineered for use in organic agriculture.

The upcycling of the Ecotan leathers may occur at different levels:- Tannery: shavings and trimmings

- Cutting rooms: scraps

- Finished products: spent leathers